As everyone knows, any vehicle requires periodic maintenance. The procedure when contacting an official dealer guarantees high quality work, although it may cost more than in other car services. Let's take a closer look at what TO-2 is, the list of works included in it, the difference from TO-1 and other features.

general information

When passing a technical inspection, regulated, control and inspection work is carried out, including diagnostics and adjustment manipulations of vehicle components on special stands. The entire list of TO-2 works is aimed at checking the main components of the vehicle. In addition, the operation involves examining the condition of the machine and carrying out a number of additional manipulations. For example, this could be an oil or filter change. Carrying out such operations does not take much time, but allows you to add reliability to your car.

TO-2 "Kia Rio"

The list of works for this machine includes the following:

- Replacing engine oil and oil filter.

- Lubricating elements of doors, trunk and hood cover.

- Brake fluid renewal.

- Checking the exhaust gas system.

- Prevention of the air filter nozzle, drive system, gearbox.

- Control of steering, tire pressure, lighting system, air conditioning, belt drive of additional components.

- Cleaning the flow block filter and body drainage holes.

The Kia Rio TO-2 is being carried out, the list of works for which is indicated above, after a mileage of 30 thousand kilometers.

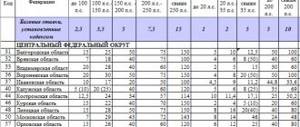

Approximate scope of work for EO, TO-1, TO-2 and STO

The list of procedures included in the maintenance depends on the mileage of the car:

- Daily maintenance.

During the EO, the vehicle is inspected for the presence of external defects of individual elements, the performance of the braking system, the integrity of lighting devices and other mechanisms are tested, and the tire pressure is determined. Daily maintenance includes washing the car and refueling it if necessary. In other words, the purpose of the EO is to ensure the operability of freight transport for the current trip. - First maintenance.

TO-1 includes checking the level of engine and transmission oil, antifreeze and other fluids in the system. Various mechanisms of the car are adjusted - steering, clutch, free play of pedals. During the first maintenance, the main components and assemblies are lubricated. Lubrication work is carried out in accordance with the card, which must be kept by the owner of the car or in the service of an official supplier or manufacturer. - Second maintenance.

During TO-2, procedures similar to the previous paragraph and a number of additional measures are performed. First, the engine oil is changed. Often, it is during the second maintenance that some important components are disassembled and repaired, which were only checked and lubricated during the first maintenance. In most cases, the service interval specified for a specific truck is similar to the period between the second maintenance. - Seasonal maintenance.

The list of works included in the service station depends on the season of the procedure. At the beginning of autumn, the truck is prepared for winter use. To do this, antifreeze is poured into the cooling system, and antifreeze liquid is poured into the washer reservoir. In some cases, the engine oil is replaced with a similar one, but with a lower viscosity. It is mandatory to check and adjust the density of the battery electrolyte. Before the onset of frost, condensate should be removed from the receivers of the pneumatic system and the dryers should be replaced. At negative temperatures, it is recommended to drain condensate 1-2 times a week. At the beginning of spring, the list of service station work is noticeably smaller, since the requirements for operating conditions in the warm season are lower, and most trucks are perfectly adapted to them.

During the year, a truck owner undergoes several types of maintenance. As practice shows, the average annual mileage of freight vehicles in Russia ranges from 40,000 (with optimal operation) to 250,000 kilometers (with intensive use without downtime). Judging by these data, trucks need to undergo maintenance 2-3 times a year, which entails significant financial costs. But this cannot be avoided - without timely maintenance, the vehicle will quickly exhaust its service life and will need serious and more expensive repairs.

"Volkswagen Polo"

The regulations are relevant for all cars of this brand produced since 2010. The provision applies to models with a 1.6-liter engine equipped with a manual or automatic transmission. The manufacturer advises to undergo technical inspection exclusively at a service center. If you decide to carry out the operation yourself, carefully read the operating instructions.

It may be noted that the oil in the gearbox is filled for the entire operating period and cannot be replaced. Its level should be checked every 30 thousand kilometers (manual transmission) or 60 thousand if you have an automatic transmission.

Below is a list of works of TO-2 “Polo Sedan”:

- Change oil, filter and cabin equivalent.

- Monitoring of ventilation systems, connecting hoses, cooling unit.

- Checking fuel lines and connecting elements.

- Maintenance of suspension and fasteners.

- Checking the tire pressure and wheel angle.

- In addition, the battery, parking brake, lighting elements, spark plugs, drain holes and closing parts are inspected.

Additionally, the list of works of TO-2 “Polo Sedan” includes replacing the air filter element, brake fluid, checking the drive belt of attachments and additional components. An inspection is carried out every 30 thousand kilometers or after two years of operation.

"Hyundai"

The second inspection period for this car is carried out after 30 thousand kilometers. An oil change is performed, as well as a number of other operations:

- Monitoring of major components, including the brake system and gearbox.

- Diagnostics of valves and engine.

- Replacing the fuel and oil filter.

- Checking belt drives.

- Monitoring the condition and amount of refrigerant.

Manufacturers recommend carrying out maintenance-2 “Solaris”, the list of works of which is indicated above, at branded stations. It is worth noting the main verification codes. Among them: I (checking components, parts and consumable components), R (replacing required elements).

Useful information

It is advisable to carry out regular maintenance of any vehicle at authorized or partner service centers. This will not particularly affect the cost, but you receive a guarantee for the work performed. In reality, it can be serviced at any service station, but in this case, if controversial issues arise, the dealer will have to prove the quality of the work performed.

When is it necessary to do TO-1? For example, TO-2 is carried out after 30 thousand kilometers or 2 years of using the vehicle (applies to most passenger cars). Therefore, the first technical inspection should be carried out a year earlier, or after 15 thousand mileage. If the car has driven less than 15,000 km in a year, it is also advisable to do an inspection in order to avoid serious breakdowns and failure of key parts.

In addition, owners should periodically check the level of brake fluid, oil, antifreeze, tire pressure and other issues related to the safety of movement.

What is included in TO 1

It is necessary to separate different types of technical passage. inspection. There are only three types - TO-1, TO-2 and SO (seasonal vehicle inspection). Let's start with the first one. The purpose of TO-1 is to prevent random failures in the operation of all vehicle mechanisms until the next inspection. These include:

- control and diagnostic work of all driving devices of the car;

- checking all fasteners of the car body;

- lubrication and adjustment work.

Most car enthusiasts recommend undergoing TO-1 at a technical service center. The fact is that a visual analysis by a non-professional (and a professional too) will not protect the owner from possible hidden problems. At the service station you will be provided with special instruments that will certainly detect a dangerous breakdown. The benefit is, in fact, obvious. The sooner you notice a malfunction and repair one of the car components, the less money you will spend on it in the future.

TO-2 "Skoda": list of works

For this car, the process is similar to other cars of a similar class. The following operations are carried out at the service station:

- Replacing the brake reagent.

- Changing the atmospheric filter with a mileage of over 60 thousand kilometers in 24 months.

- Checking the condition of the tires.

- Inspection and lubrication of active elements of doors, hood and trunk.

- Replacing the oil filter. If the mileage exceeds 60 thousand kilometers on gasoline and 100 thousand kilometers on diesel power plants.

- Checking the spark plugs.

- Diagnostics of the level of other working fluids, the condition of the battery and seat belts.

Deadlines

TO-1, TO-2, the list of works and the frequency of which vary, require special attention from the owners. Manufacturers recommend undergoing the first technical inspection no later than a year after using the car or driving 15 thousand kilometers. The second check should be carried out two years after purchasing the vehicle or upon reaching 30 thousand kilometers.

The specific determination of the timing of a technical inspection depends on the driver’s personal driving style and the operating conditions of the car. For example, driving short distances does not have as active an effect on the wear of parts as driving long distances under maximum loads. It is important to know that the brake fluid in any case must be updated at least once every two years. If this point is ignored, the brake unit may fail, which can lead to an emergency driving situation.

What is included in TO 2

TO-2 is a more in-depth inspection of the car. As a rule, with TO-2, TO-1 is also carried out completely. The fundamental difference between these two processes is that during TO-2, auto technicians adjust, configure, analyze or repair vehicle components with their complete or partial disassembly. This does not happen with TO-1. The complexity of this work is really high, so only car maintenance service professionals can cope with the task. However, it is no secret that many car enthusiasts attempt to independently configure and disassemble car components, which sometimes leads to serious consequences. After all, it is necessary not only to correctly disassemble and repair the unit, but also to put the part in the same place as it was there. Well, one more point in favor of handing over the car to a maintenance service is the special equipment with which car repairs are carried out. It is unlikely that you have half of the useful tools in your garage that are necessary for effective maintenance of your car.

Notes

Maintenance 2 of a car, the list of works of which is indicated above, requires compliance with certain rules specified by the manufacturer. Information about the category of the type of oil used can be found in the operating instructions. The recommended grade and type of this petroleum product is also given there. When performing a technical inspection, special attention must be paid to replacing not only the oil, but also its filter element.

It is also worth checking the thickness of the brake linings. Especially if the car was used in an extreme driving style. It is also advisable to check the reset of the service interval indicator and the compliance of the condensate drainage from the fuel and air filters.

Maintenance 1 is carried out every 4 thousand km

Every 4,000 km, a Ural truck must undergo maintenance according to the TO-1 scheme. To perform maintenance at maintenance 1, you must do the following:

- Wash the power steering pump filter, check the oil level in the reservoir and top up if necessary. The oil level should be between the upper and lower marks with the plug open.

- Tighten the nut of the telescopic shock absorber housing (later tighten if a leak appears).

- Lubricate the clutch release clutch bearing and the clutch release fork shaft bushing.

- When driving on our roads, and even more so off-road, vibration and shaking can weaken the fastenings of the main corners and mechanisms. To avoid breakdowns, tighten the fastenings of all main components - the power unit, air intake and exhaust systems, step-ladder nuts of the front and rear springs, nuts of the wedges for fixing the pins of the front springs and the ears of the front springs. Remember, it is necessary to tighten the nuts of the spring ladders on a fully loaded vehicle.

- Check the tension of the steering pump drive belt. The deflection should be from 7 to 13 mm.

- Brake linings are subject to constant wear, so adjust the gap between the brake pads and drums. After adjustment, the brake drums should not become hot.

- Check the level and density of the electrolyte in the batteries. If necessary, add distilled water and recharge the battery. The electrolyte level should be within 10-15 mm above the safety shield.

- It is recommended to periodically clean the surface and ventilation openings from dirt and dust. Check that the contacts of the wire tips are securely attached to the battery.

- Pump in grease until fresh grease emerges from the pin and eyelet interface of the front spring. When working with a trailer, do the same with the tow bar bushing. Remove excess grease with a rag.

- Check and, if necessary, bring the lubricant level in the steering knuckle housings of the front drive axle to normal. The lubricant level should reach the edge of the inspection filler hole. Oil leakage through the plugs is not allowed.

- When carrying out TO-1 work, it is necessary to carry out maintenance of the power unit in accordance with the engine operating instructions.

Peculiarities

For the domestic car "Lada Kalina" TO-2, the list of works for which is indicated above, plays an important role, taking into account the condition of the roads and the method of operation. Maintenance, in accordance with the established regulations, allows you to extend the working life of vehicle components and ensure the safety of movement. Many basic works can be carried out independently, following the recommendations specified in the instruction manual.

The frequency of technical checks for the Lada Kalina is provided every 15 thousand kilometers. For the foreign Volkswagen Polo sedan, TO-2 (list of works) is almost identical, with the exception of checking different types of engines and gearboxes. The average cost of a technical inspection at a branded service station for a public car is about seven and a half thousand rubles. Additionally, you will have to spend money on consumables, if necessary.

What is CO?

We have figured out what is included in vehicle maintenance. Now let's talk about seasonal maintenance (SO). In fact, CO implies the very “re-shoeing” of the car with winter or summer tires. However, CO is not limited to this. Some services offer additional services, such as anti-corrosion coating of the car body and so on. As a rule, CO is carried out together with TO-2, which makes the task easier and saves you money and time.

And finally, I would like to highlight such an important topic as the regulations for passing any maintenance. It is known that the traffic police requires the driver to comply with the maintenance regulations, but they do not specify what they are exactly. What is the reason? And the reason is that for each car and each specific model, its own specific regulations are established. Moreover, this is done by the manufacturer of your steel horse. You can find a description of the necessary procedures within the framework of TO-1 and TO-2 in the vehicle operating instructions. In addition, it lists all the characteristics of the various components of the car and their approximate “exposure” based on the number of kilometers traveled. The list of necessary procedures should also be described in the book.

What is included in the maintenance of the car you drive? It is best to find out about this at a car service center. And in general, the most correct choice when deciding whether to undergo another inspection is to work with a car service center. The service center staff will not only offer you a complete check of the car, but will also point out possible future breakdowns.

Oil selection and change

All passenger cars undergoing inspection at variable intervals are filled with special motor oil at the factory. Let's look at the features using the example of a Skoda car. This indicator has the following positions:

- For gasoline power units - VW-503.

- For diesel engines with particulate filtration - VW-506 01.

- For other engines – VW-507 00.

The use of these types of oil allows you to ensure the most correct use of the vehicle, as well as reduce costs during maintenance.

If the factory supply of oil is not enough, it is replaced once a year or when the mileage reaches 15 thousand kilometers. For correct operation of all systems, it will be necessary to recode the machine for specific service inspection intervals. Details can be obtained from a representative of an official service station. In any case, the manufacturer recommends changing the engine oil every 15 thousand kilometers and conducting a second inspection after two years of operation or 30 thousand kilometers. Brake fluid needs to be updated every couple of years.

If the car is equipped with a diesel power unit with an increased sulfur content, the oil change period is reduced to seven and a half thousand kilometers, which is due to the design features of the engine.

Other types of maintenance

Depending on the age of the car and the mileage covered, not only mandatory maintenance 1, 2, 3 are carried out, the list of works of which will be discussed below, but also subsequent checks, up to the tenth inspection.

The first technical inspection includes work on replacing fuel and lubricants and processing fixing elements. The following manipulations can also be performed:

- Replacing the oil filter kit.

- Lubrication of gearbox parts.

- Checking the exhaust, brake and steering systems.

- Steering control.

- Tire pressure measurement.

- Checking lighting fixtures and battery.

- involves a small amount of work on replacing fuel and lubricants and components, as well as lubrication of component elements.

The inspection also includes cleaning the drainage holes in the body, replacing the brake fluid, and identifying possible manufacturing defects.

The parameters for the second maintenance were discussed above. Next, we will study the features of subsequent operations in terms of timing and capabilities.

Maintenance 2 is carried out every 16 thousand km

When the mileage of a Ural truck approaches 16,000 km (and then every 16 thousand km), it must undergo extended maintenance or TO-2. It includes the entire scope of work performed during TO-1, as well as:

- Check and, if necessary, tighten the fastenings of the radiator, air filter and hose connections of the air intake system, and the fastening of the exhaust pipe muffler.

- Drain the fuel tank sediment and make sure there are no fuel leaks through the drain plug.

- Adjust the free play of the clutch pedal. It should be within 50-60 mm, in the absence of air pressure in the car’s pneumatic system.

- Tighten the fastening of the cardan shaft flanges and the fastening of the intermediate support to the beam; tighten the fastening of the main gears of the drive axles.

- Check the tightness and, if necessary, tighten the fastening nuts: the lever of the upper and lower covers of the steering knuckles and the flanges of the ball joints; reaction rod fingers; steering gear housing; steering shaft cardan forks; steering rod fingers; boosting mechanism.

- Check the tightness and, if necessary, tighten the bolts: upper reaction rod brackets; the balancer axle assembly to the balancer brackets; front brackets of the front springs to the lower flange of the side member; rear brackets of front springs to side member reinforcements; balancer brackets to the frame cross member; tie rods for the rear brackets of the front springs; fifth wheel to the subframe and frame (for truck tractors).

- Check the condition of tires, wheels and their fastening.

- Adjust the free play of the steering wheel and the toe-in of the front wheels.

- Check that the starter is securely attached to the engine.

- Check the condition of the insulation of electric drives and their fastening. If damaged, wrap the damaged areas with insulating tape.

- Check and, if necessary, tighten the fastenings of the power take-off, cab, platform and tail.

- Place the unloaded vehicle on a flat, horizontal platform and adjust the headlights.

- Check the oil level and, if necessary, add to the correct level: in the transfer case housing, intermediate support of the propeller shaft, in the main gears of the drive axles, in the rear balancer suspension hubs, in the steering gear housing. The oil level should reach the edge of the filler inspection hole. Oil leakage through plugs is not allowed

Using a lever-plunger syringe, according to the lubricants and working fluids map:

- Fill the upper bearings of the pins with lubricant through grease nipples in the amount specified in the lubricants and working fluids chart;

- Disassemble the splined joint of the steering propeller shaft and lubricate it;

- Lubricate the splined joints of the intermediate and middle axle drive shafts and the water pump bearings through a grease gun until fresh grease is squeezed out;

- Pump until fresh grease is squeezed out into the reaction rod joints. If the o-ring is significantly deformed, fresh lubricant is not necessary.

Mileage inspection period

The Volkswagen car (TO-2, the list of works is indicated in the article) requires regular follow-up inspection, like most types of vehicles. Among the technical inspections we note the following:

- TO-3 is carried out after 45 thousand kilometers and includes work typical for the first technical inspection.

- TO-4 is performed after four years of vehicle operation or 60 thousand kilometers. The inspection includes the work provided for the first and second inspection, as well as replacing spark plugs, checking the condition of the timing chain or belt mechanism, checking the tensioner and oil pump device.

- TO-5 is an analogue of the first maintenance, carried out after 75 thousand km.

- TO-6 - after 90 thousand km, work similar to TO-1 and 2 is performed.

- TO-7, 8, 9, 10 are produced after 105, 120, 135 and 150 thousand kilometers, respectively.

Second maintenance (TO-2)

Table 2. List of work performed during maintenance (second maintenance - TO-2)

| Maintenance operation | Accessories and tools | Basic instructions |

| When carrying out the second maintenance, in addition to the first maintenance work, it is necessary to perform the following work: | ||

| Engine, cooling and lubrication systems | ||

| 1. Check and, if necessary, tighten the nuts securing the beam of the front and rear engine mounts to the frame | Keys 17x19, 19x22 | The nuts must be tightened to the following torque: front support - 44-62 N*m (4.4-6.2 kgf*m), rear support - 70-100 N*m (7-10 kgf*m) |

| 2. Check and, if necessary, tighten the nuts securing the exhaust pipes of the muffler to the exhaust manifolds, the muffler brackets with the frame and the step-ladders of the muffler exhaust pipe from the transverse frame. Check the condition and tightness of the connection of the sealed hose with the muffler and exhaust pipes | Box wrenches 17x19, 13x17 wrenches 13x17, 17x19 | All nuts must be tightened. The stepladders should press the exhaust pipe tightly against the frame cross member. The passage of exhaust gases, burnout, kinks, cracks of pipes and muffler are not allowed |

| Clutch | ||

| 3. Check the free play of the clutch pedal and adjust if necessary | Wrenches 13x17, 19x22, pliers, hammer, ruler, screwdriver | The pedal free play should be within 34-43 mm when the air is purged from the system |

| Transmission | ||

| 4. Adjust the position of the gearbox support | Wrenches 22x24, 2x30, pliers, hammer, screwdriver | |

| 5. Check and, if necessary, tighten the nuts securing the intermediate mechanism of the box with frame | Spanners 13x17, 17x19 | |

| 6. Check the fastening of the transmission support bracket to the frame cross member, tighten if necessary | ||

| Steering and front axle | ||

| 7. Check the condition of the oil seals and seals of the steering gear housing | Oil seals must not be damaged, oil leakage is not allowed | |

| 8. Check the cotter pins of the nuts, steering rods, power steering and, if necessary, correct the faults | Pliers, screwdriver, wrench 27x30 | The nuts must be cottered |

| 9. Check the condition of the thrust bearings and the tightness of the king pin nuts and, if necessary, correct the faults | Socket wrench 50x55, screwdriver, hammer, set of probes | |

| 10. Check the condition of the front axle beam, the amount of toe-in and the steering angles of the front wheels | A ruler for checking toe-in and a device for measuring the alignment angles of the front wheels | The toe-in of the front wheels should be within 3-5 mm |

| 11. Check and, if necessary, tighten the nuts securing the steering gear housing, the steering column bracket, the power steering pump bracket, the nuts of the pinch bolt securing the rear power steering support pin | Replaceable head 13 and 36, wrench, screwdriver, spanners 13x17, 17x19, 22x24, 24x27 | All nuts must be tightened |

| 12. Check and, if necessary, adjust the tension of the power steering pump drive belt | KP-1609A, key for turning the crankshaft | |

| Brake system | ||

| 13. Remove the front hubs, check the condition of the brake wheel mechanisms, as well as the wheel bearings and, if necessary, replace worn parts. Adjust the front wheel hub bearings. If necessary, tighten the nuts securing the brake drums to the hubs and, through one TO-2, tighten the nuts securing the front brake calipers to the steering knuckles | A device for removing hubs, a special wrench for hub bearing nuts, a wrench, a hammer, a wrench 22x24 | The linings must not have cracks, chipping or scuffing. Loosening of the rivets and wear of the linings on the recesses of the rivet heads by less than 1.0 mm are not allowed |

| 14. Check the condition and thickness of the friction linings of the rear foot brakes | Wrench 13x17 | |

| 15. Check and, if necessary, tighten the nuts securing the air cylinder clamps | Wrench 17x19, replaceable head 17, wrench | |

| Chassis | ||

| 16. Check the condition of the fastening of the spring brackets and the fastening of the bracket liners | ||

| 17. Check the correct location (absence of distortions) of the front and rear axles and, if necessary, eliminate distortions | Roulette RS-2, or RZ-2, or RZh-2 | |

| Check and, if necessary, tighten the nuts of the spring ladders, pins and ladders of the spring ears | Lift with wrench, head 38, wrench, head 32, wrench 24x27 | Tighten the stepladder nuts with the springs straightened, the tightening torque for the rear springs is 600-650 N*m (60-65 kgf*m), for the front springs - 400-450 N*m (40-45 kgf*m). The pin nuts must be tightened; Tighten the stepladder lug nuts to torques of 27-50 N*m (2.7-5 kgf*m). The bushings must not be damaged |

| 18. Check the condition of the shock absorber bushings and replace if necessary | ||

| 19. Check the fastening of the towing device to the frame cross member, the tightening and cotter pins of the slotted nut, and correct any faults if necessary. If the vehicle is constantly working with a trailer, remove the towing device from the vehicle and eliminate any identified defects. | Wrench 46x50, socket wrench 24x27, head 30, wrench, screwdriver, pliers, mulottok | |

| 20. Check and, if necessary, tighten the nuts securing the spare wheel bracket | Wrench 19x22 | |

| 21. Check the condition of the rims and wheel clamps | ||

| Cabin, platform and tail | ||

| 22. Check and, if necessary, tighten the nuts securing the platform stepladders | Socket wrench 19 x 22 | |

| 23. Check and, if necessary, tighten the nuts securing the fuel tank brackets | Wrenches 17x19, 19x22 | |

| Supply system | ||

| 24. After one TO-2, check and, if necessary, adjust the fuel injection advance angle | Replaceable head 12, knob | |

| 25. After one TO-2, remove the injectors from the engine, check their operation on the stand and adjust | Wrench 17x29, replaceable heads 13 and 17, wrench, special wrench for injectors | |

| Electrical equipment | ||

| 26. Check the degree of charge of the batteries by electrolyte density and cell voltage under load and, if necessary, remove the batteries for recharging | Load fork PE-2, rubber gloves, wire lug puller | The voltage of each element under load for 5 s is not lower than 1.6 V in summer and 1.7 V in winter |

| 27. Inspect the generator and starter and, if necessary, clean their surfaces from dust, dirt and oil | Rags, brushes | |

| 28. Check the tightness of the starter coupling bolts and tighten if necessary. Check the tightness of the wire lugs to the starter terminals | Wrenches 13x17, 17x19, screwdriver, pliers | |

| 29. Check the installation of the headlights and the direction of their luminous flux. Troubleshoot if necessary | Screwdriver | |

| 30. Check and, if necessary, tighten the generator mounting bolts | Wrench 12x13 | Bolts must be tightened |

| Lubrication and cleaning work | ||

| 31. Carry out lubrication and cleaning work in accordance with the lubrication chart | ||

| Additional work on dump trucks and tractors | ||

| 32. Check the condition and adjustment of the bypass valve cable and, if necessary, adjust the platform lift angle | Wrenches 12x13, 13x17, 19x22, 24x27, 32x36, 36x41, screwdriver | |

| 33. Check the fastening and tightness of the power take-off and oil pump, and if necessary, correct the faults | Wrenches 12x13, 13x17 | |

| 34. Unscrew the plug in the bottom of the hydraulic cylinder and drain the sediment | L-shaped wrench for 10 mm plugs, funnel for draining oil | |

| 35. Check the condition of the fifth wheel of the tractor, the fastening of the grip lock handle of the fifth wheel to the frame, the condition of the locking knuckle grips and the latch spring | Wrenches 17x19, 22x24, pliers | |

List of works during maintenance-2

Adjustment according to the service life of the car

As experts advise, the refrigerant should be replaced at least once every 3-5 years. The process involves completely replacing the coolant or replenishing it to the required level. For example, Volkswagen Polo cars are filled with purple refrigerant of the G-12 Plus type. The liquid can be mixed with analogues G-12 and G-1. When mixing solutions, the proportion is 1/1. The total volume of the system is about six liters.

According to the official vehicle maintenance regulations, the oil in the gearbox is designed for the entire service life of the vehicle. When performing maintenance, only its level is monitored, and the period of the next inspection should not exceed 30 thousand kilometers for a manual transmission and 60,000 for an automatic transmission.

The manual unit holds two liters of SAE 75W-85 (API GL-4) transmission oil, and the automatic unit holds about seven liters of a synthetic analogue of the ATF brand (G055025A2).